Purchase Order is a crucial document to ensure the procurement of goods exactly as per the requirements of the company. A purchase order is a contract between the buyer and seller and proves to be a legal document for reference in case of any discrepancies or disputes in the goods exchanged.

In this article, we will cover all aspects right from what is a purchase order, who prepares it, what information it contains, why is it significant, and how to generate the purchase electronically via ERP software.

What is a Purchase Order (PO)?

A Purchase Order popularly referred to as PO; is a document issued by the purchaser to the seller. It is a formal proposal to buy products and provides complete details of terms and conditions for the transaction.

Typically, the purchase order specifies the exact details for the product (make, grade, design), quantity, price agreed upon, scheduled delivery date(s), payment terms, shipping instructions, and other terms & conditions (if any). We will cover this in more detail in the next section.

This ensures minimal chances of errors or misunderstanding and the correct goods are delivered at the right time & right place. Let us now see what a purchase order contains

What Information is provided in the Purchase Order (PO)?

A purchase order typically contains the following details:

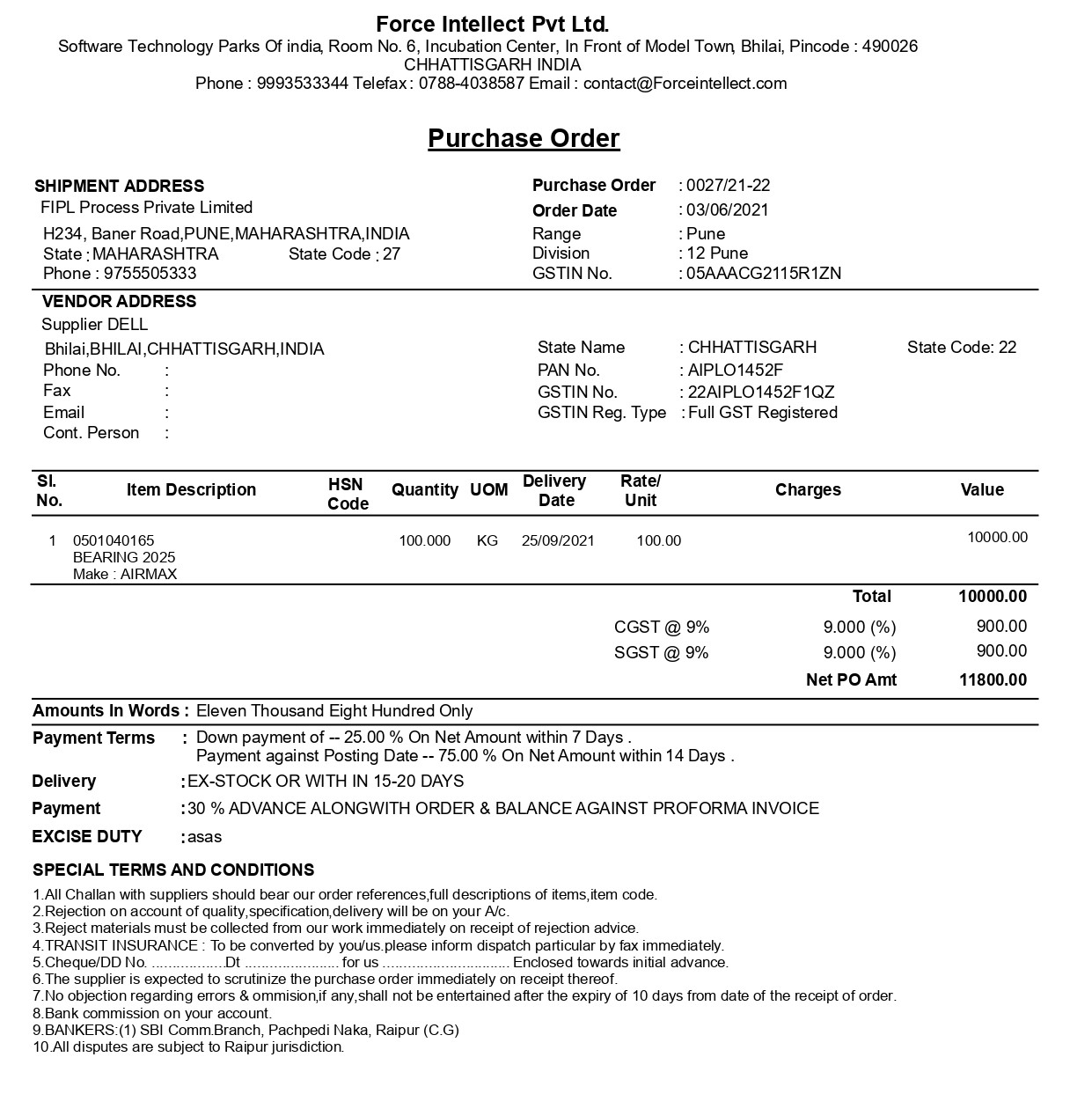

- PO Number & PO Date: A unique number used for tracking all details of the purchase, issue date, and delivery date and for reference purposes.

- Parties’ information: Mentions Buyers and Suppliers name, full correspondence address and Tax registration numbers. Purchase order should also have contact details of concerned persons from Buyer & Seller side.

- Consignee Addresses: Details of the consignee as sometime location where material is required may be different from buyer’s location. Purchase Order should have addresses of all consignee locations, as sometimes deliveries are required at more than one units/location of company.

- Item Description: Comprehensive details of the list of products to be purchased with description, E.g., make, model, design, size, shape, length, etc.

- Technical specifications: This is a sub section of the item description and may be required in case of certain items where more detailed specifications are required. E.g., An item – Motor 3.3 KW, may have technical specifications such as Squirrel cage, 3000 RPM, 3 phase, etc.

- Quality Parameters: Some items such as raw materials, may need detail quality parameter values. This helps in determining the quality expectations from the supplier. E.g. Purchase order for Coal may have following quality parameters requirement such as FC%, Ash%, Moisture% etc.

- Quantity: Quantity of items being ordered for each item in the list along with their unit of measurement (E.g., Numbers, Litres, Kgs, Tonnes etc)

- Delivery Schedule: The date/dates (if staggered) on which deliveries must be received along with the quantities.

- Unit Price: The price per unit for items being purchased.

- Total Price: Total amount for each item being purchased (Units * Price)

- Freight Terms: This defines who will arrange for the transportation of goods. And who will bear the cost of the transportation

- Other Expenses (if any): Some time some other expenses are required to execute the purchase order. It is required to tag these expenses to determine the right landed cost and bill processing for relevant expenses. E.g., Dispatch for some materials may need loading / unloading services or packing services, which may be done by third-party on actual price basis.

- Payment Terms:Specific details such as advance payment amount, payment against delivery, payment against invoice, credit days, mode of payment (cheque, NEFT, etc).

What is the Purchase Order (PO) Format?

Who/Which department prepares Purchase Order (PO)?

Most manufacturing companies have a dedicated Procurement department for the procurement of goods. They are responsible for sourcing the materials in the right quantity, at the right price, and at the right time. The primary responsibility for issuing Purchase Orders is of the procurement team.

When is a Purchase Order Issued/Prepared (PO)?

Whenever manufacturing companies need to purchase raw materials, consumables, or capital items, they raise an internal request. Once that gets approved by the concerned authorities the procurement team gets into action. They find suitable suppliers for the required products either from their database or by floating RFQ and receiving quotations to select the most appropriate vendor.

After the final rounds of negotiations with suppliers regarding prices, delivery dates, and other terms and conditions are finalized, the procurement department issues a Purchase Order.

Example of a Purchase Process

What are the benefits of preparing a Purchase Order (PO)?

- Compliance, Responsibility & Accountability: Purchase order ensures compliance with policies, and guidelines set up for purchasing. It ensures only authorized approvals and minimizes risks of fraud/favoritisms etc. Thus, it enables a fair, transparent procurement process. It brings responsibility & accountability within the team.

- Spend & Budget Management: Purchase orders mention exact prices and quantities and help ensure spending is within the specified budget. This helps identify any variance in estimated vs actual spending. Also keep a track of department-wise budget vs spend.

- Inventory Management: Purchase orders provide clarity of the amount of goods to be received and delivery schedules. This helps prevent situations of stockout or overstocking. It also enables better inventory management

- Legal Document: A purchase order is a contract between the buyer and seller. Details of the transaction, terms & conditions mentioned therein; serve as a reference point for resolving disputes or discrepancies, (if any).

What are the benefits of Generating Purchase Order (PO) Electronically or via ERP?

Traditional paper-based purchase order preparation is a time-consuming process. It takes a longer time to prepare, depends on the availability of respective persons for physical approval, needs manual follow-up, and is prone to manual errors.

Preparing purchase orders with ERP software offers the following advantages:

- More Accuracy: Using ERP software to generate purchase orders reduces the chances of manual or data entry errors. This ensures purchase orders are accurate.

- Easy Accessibility & Sharing: Soft copies can be easily accessed and shared via email, mobile apps, and collaboration tools across departments, and vendors.

- Speed up process: ERP reduces the time and effort required to generate purchase orders. Moreover, purchase orders can be reviewed, and approved even on the Go – via emails or mobile apps. This speeds up the purchase requisition & approval process.

- Implementation of Procurement Policy: Purchase order lays foundation for ensuring the procurement policy is followed religiously. It ensures purchases are done as per processes defined. Approval & authorization of PO ensures purchases are within budget specified. PO serves as a legal document for enabling transparency in purchase process as well as compliance for audit purposes.

- Real-Time Visibility: ERP offers real-time visibility & tracking of purchase orders. You get complete details of when issued, approved, if pending approval – where it is stuck for approval, etc.

- Save Costs: Software-generated purchase orders save costs associated with efforts required, paper, printing, courier, etc.

Summary

Purchase order serves as the foundation of the procurement process. It provides a structured framework for ensuring transparent dealing between buyer and seller. It ensures compliance, responsibility, and accountability. Leveraging ERP software for purchase order generation streamlines digitizes, and automates the procurement process and enables significant time & cost savings.

Ensure an efficient Purchase Process: Request a Demo of Spectrum ERP Software Now!

You may also like to read more about eProcurement solution here.

Contact Us for more details