Multiple vehicles, waiting to be loaded with goods, is a very common scene in a steel factory. Now, just imagine, if the loading team does not have any idea of what needs to be loaded, in which vehicle, this can lead to major confusion and chaos. Loading advice is that document, which clearly specifies which goods are to be loaded in each vehicle including information of product types, products specifications, quantity, and any specific loading instructions for the products to be loaded. This helps ensure accuracy & efficiency in the loading process.

Let us now understand what is loading advice, why it should be prepared, what information it contains and its specific benefits for the steel industry.

What is a Loading Advice?

Loading advice provides instructions for loading steel products into the vehicles. It provides comprehensive details of steel products being dispatched from the factory.

It contains crucial information such as:

- Type of Steel products: E.g. Round Bar / Hex Bar / Wires etc

- Specifications: E.g., Size, Length etc.

- Quantity of Steel: E.g. 25 Tonnes

- Consignee Address: E.g. XYZ Company, Bhilai, Chhattisgarh

- Specific requirements (if any):

Why Prepare a Loading Advice?

Here are some specific reasons why it is important in steel industry

- Accurate Information: Loading advice provides detailed information contents of each shipment, including product details, quantities. This ensures the correct size, type, and quantity of steel products are loaded into the vehicles and dispatched. It minimizes the chances of errors or discrepancies in dispatches and ensures correct goods reach the customer.

- Optimizes Loading Process: It makes loading process more organized and systematic. It helps warehouse personnel load products in a logical order, maximizing space utilization and preventing damage. This minimizes the time required for loading, and improves efficiency

- Resource Planning: It assists in better resource planning. It enables companies to schedule the necessary equipment and personnel for loading and unloading operations

- Standardization & Consistency: It ensures consistent loading procedures are followed while loading all the vehicles. This saves time and increases efficiency.

Who Prepares the Loading Advice & when?

The steel company’s Sales or logistics department prepares the loading advice just before the shipment is dispatched. The concerned person compiles all the relevant information, in the specified format. This makes it easy for inspection and verification that rights goods are being dispatched.

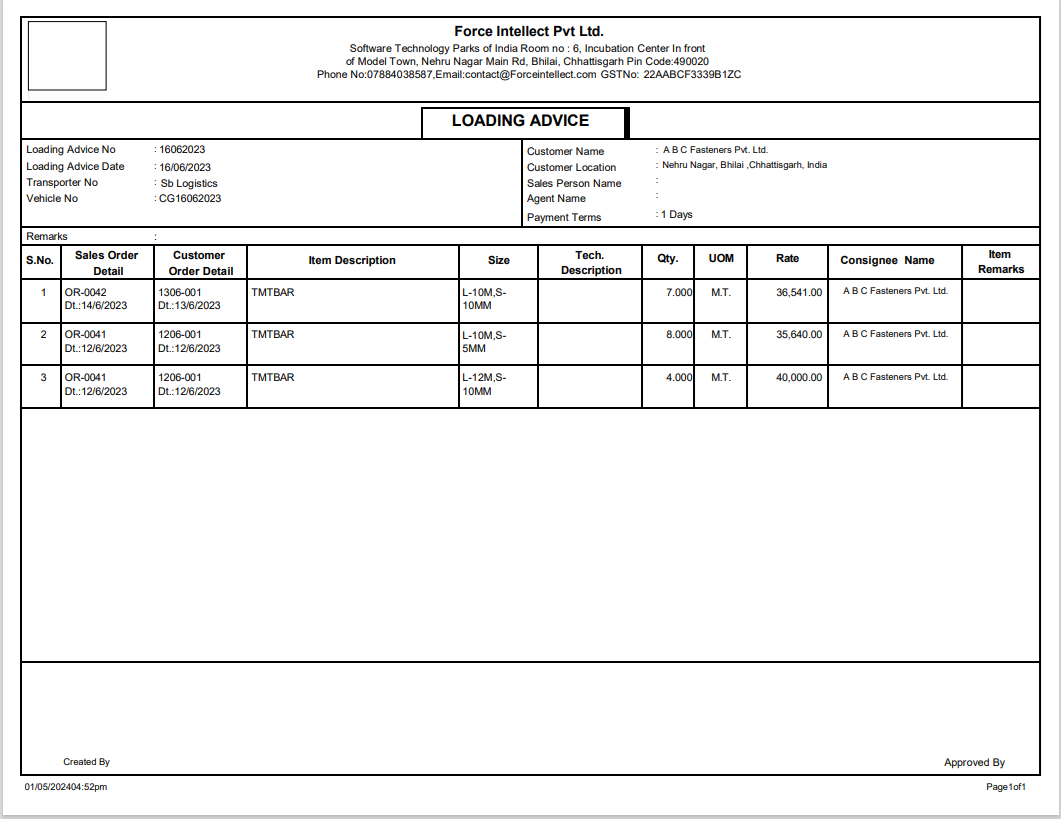

What Does a Loading Advice Look Like?

A standard loading advice must include the following details. Steel companies may customize the same as per their products and shipping preferences.

- Buyer’s & Consignee Details: Provides company name, address, contact details of buyer & supplier.

- Product Information: Details of steel – type, make, grade, dimensions, quantity.

- Transport Details: Vehicle information, driver details

- Material Location: Location of the rack from where the material should be picked.

- Special Instructions: Specific instructions given by customer (if any). E.g., Loading sequence for material to be dispatched.

- Authorized Signatures: Signatures of authorized persons to confirm the accuracy and approval of loading advice.

Format of Loading Advice for Steel Industry

Benefits of Loading Advice for the Steel Industry

Loading advice plays a significant role in improving the loading operations efficiency and ensuring timely & accurate delivery of steel products to the correct consignees

Loading advice also contributes to steel business success in following ways:

- Better Inventory Management: Loading instructions enables manufacturers to plan for the dispatch of goods from manufacturing facilities as per their delivery commitments. This helps effectively manage dispatches as per the inventory availability and reduces chances of mistakes or disorder.

- Streamlines Loading Processes: Loading advice offers clear instructions for systematically loading products, minimizes wasted time & resources, and maximizes utilization and load capacity. This eliminates any confusion or person-dependency and standardizes processes. It reduces loading time and improves efficiency.

- Customer Satisfaction: Properly loaded shipments lead to more accurate and timely deliveries. This gives the customers confidence in your ability to deliver quality products reliably & in timely manner, leading to customer satisfaction & repeat orders.

Summary

Loading Advice provides comprehensive and accurate information for loading of the goods. It serves as the foundation for efficient dispatch of right steel products from the manufacturing facility to the concerned companies. It optimizes dispatch efficiency, ensures timely correct deliveries, and boosts customer satisfaction.

Read more about our ERP for Steel Industry here